Systems Refractory Solutions launches to advance refractory maintenance services in steel mills

The launch of Systems Refractory Solutions reflects an increasing demand within the metals industry for dedicated refractory expertise — an area that is critical to the uninterrupted operation of steelmaking infrastructure

The Systems Group has launched a new business unit, Systems Refractory Solutions, a specialised provider of refractory maintenance services dedicated to the steel industry. The company will deliver high-quality, safety-focused refractory maintenance solutions designed to enhance reliability, extend equipment life and reduce downtime at steel mills across the United States. Led by Josh Smitsky, with over 20 years in the refractory industry, and Mike Williams, with over 30 years in steel mill melt shops.

“Our mission at Systems Refractory Solutions is to provide steel mills with refractory maintenance services that not only meet industry standards, but set new benchmarks in operational efficiency and safety,” said Kyle Morgan, president of The Systems Group. “We are excited to bring a focused, expert team to support critical refractory systems — minimising downtime and helping our customers succeed in an increasingly competitive landscape. We aim to replace the dime a dozen refractory maintenance services with a new standard in service, reliability and safety.”

Systems Refractory Solutions offers a comprehensive suite of refractory maintenance services, including:

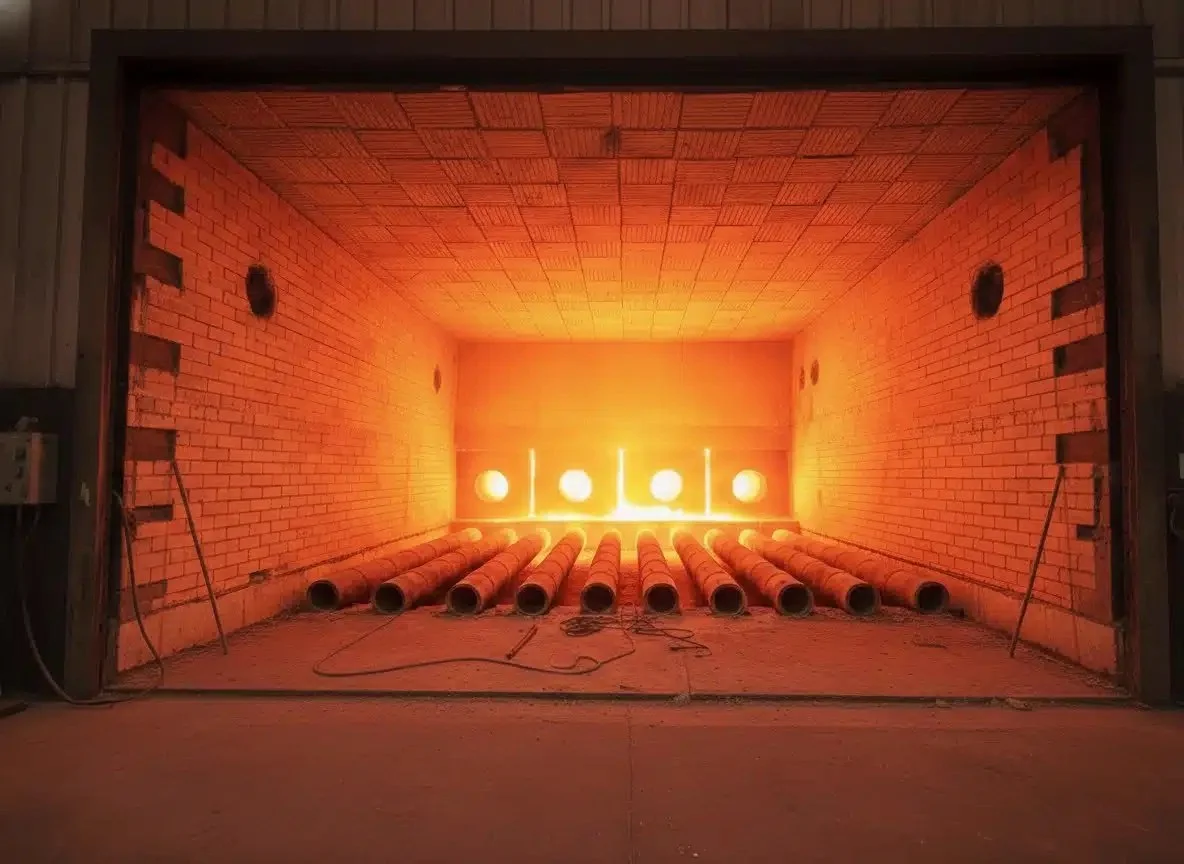

Routine refractory inspections and condition assessments, specialising in reheat furnaces

24/7 emergency refractory repair services

Maintenance planning and lifecycle support

Refractory relining and refurbishment

Turnkey shutdown projects

Brick installation

Plastics – ram or gun

Gunite installation

Shotcrete installation

Castable pumping and forming

Ceramic fiber installation

Ceramic fiber pumpable on running units to cool hotspots to reduce downtime

Precast shape installation

Prefabricated fiber lined units

Ladle relining

Furnace door lining repairs

On-site technical expertise from trained refractory specialists.

By concentrating on refractory maintenance, the company aims to solve the unique high-temperature wear challenges faced by melt shops, furnaces, ladles, tunnel and reheat furnaces and other critical components in steel production facilities.

The launch of Systems Refractory Solutions reflects an increasing demand within the metals industry for dedicated refractory expertise — an area that is critical to the uninterrupted operation of steelmaking infrastructure. With deep experience in steel mill services and engineered solutions, Systems Refractory Solutions is positioned to become a trusted partner to operations seeking maximum uptime and cost-effective refractory lifecycle management.